Table of contents

Holding and Lifting

Transporting with

Lifting magnets

Electro-permanent and electro-magnetic systems for a wide range of applications

Product Overview - Hold & transport

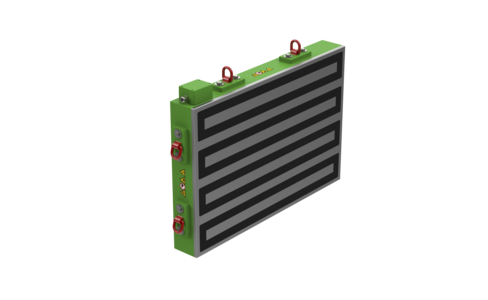

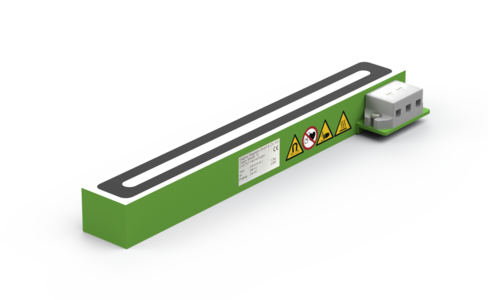

Electro-Holding-Magnet 511For holding and straightening sheet metal with particularly high holding forces.SERIES 515

Electro-Holding-Magnet 511For holding and straightening sheet metal with particularly high holding forces.SERIES 515 Electro-Holding-Magnet 515For economical holding in production and fixture construction, especially with very thin sheets.SERIES 535

Electro-Holding-Magnet 515For economical holding in production and fixture construction, especially with very thin sheets.SERIES 535 Electro-Holding-Magnet 535For economical holding in production and fixture construction.SERIES 536

Electro-Holding-Magnet 535For economical holding in production and fixture construction.SERIES 536 Electro-Holding-Magnet 536For economical holding of ferromagnetic parts with high holding forces.SERIES 518

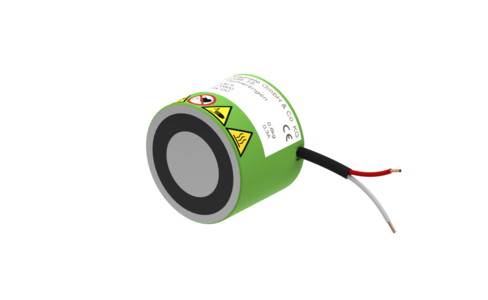

Electro-Holding-Magnet 536For economical holding of ferromagnetic parts with high holding forces.SERIES 518 Electro-Lifting-Magnet 518For handling and transporting steel products.SERIES 536

Electro-Lifting-Magnet 518For handling and transporting steel products.SERIES 536 Electro-Lifting-Magnet 536For automated transport and handling of steel products.SERIES 5180N

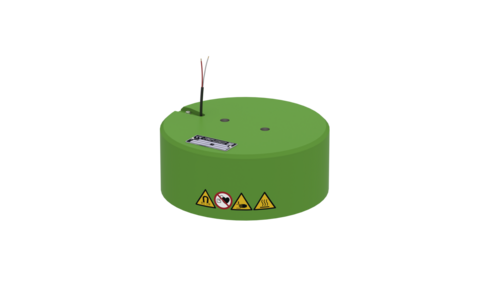

Electro-Lifting-Magnet 536For automated transport and handling of steel products.SERIES 5180N Electro-Permanent-Lifting-Magnet 5180NHigh load-bearing capacity thanks to integrated double magnet system.SERIES 5190N

Electro-Permanent-Lifting-Magnet 5180NHigh load-bearing capacity thanks to integrated double magnet system.SERIES 5190N Electro-Permanent-Lifting-Magnet 5190NWith integrated bipolar double magnet system.Traverse

Electro-Permanent-Lifting-Magnet 5190NWith integrated bipolar double magnet system.Traverse Lifting-Beam for circular partsSafe and flexible handling of round partsTraverse

Lifting-Beam for circular partsSafe and flexible handling of round partsTraverse Not adjustable Lifting-BeamSimple, cost-effective and versatile.Traverse

Not adjustable Lifting-BeamSimple, cost-effective and versatile.Traverse Customized Lifting BeamsMaximum stability, safety and creative solutions.Traverse

Customized Lifting BeamsMaximum stability, safety and creative solutions.Traverse Adjustable Lifting-BeamUniversal flexibility and safety.

Adjustable Lifting-BeamUniversal flexibility and safety. Two magnet variants

Electric lifting magnets & permanent electric lifting magnets

- Electric lifting magnets: This type of magnet works with electrical energy and generates a magnetic field when current flows through the coil. They can be manufactured in different sizes and load capacities and are ideal for use with heavy loads.

- Electro-permanent lifting magnets: This type of magnet uses a combination of electric current and permanent magnetism to create a magnetic field. They are more energy efficient than electric lifting magnets and can hold their load even during power outages or other disturbances in the electrical circuit.

VERSATILE APPLICATIONS

For logistics through to recycling

- Lifting and transporting steel sheets, shafts, slabs, pipes, blanks, profiles, beams, moulded parts, castings, workpieces

- Order picking of steel parts

- Automation of transport tasks

WAGNER trusses

For optimised heavy-duty transport.

Safety is the top priority when transporting large components. With its customised lifting beams, WAGNER MAGNETE offers a convincing answer to the requirements of transporting bulky and heavy loads. Our customised lifting beam solutions stand for maximum stability and the highest safety standards to ensure that your valuable loads reach their destination safely.

Whether you opt for the flexibility of our adjustable lifting beams, prefer the solid construction of our rigid models or require customised lifting beams for special challenges - we have the right solution to make your processes safer and more efficient.

Influences on the load-bearing capacity

AIR GAP, DIMENSIONS, SURFACE FINISH AND MATERIAL

Influence of air gap

Influence of the workpiece dimensions

The field lines of the magnetic circuit close over the cross-section of the material to be transported, causing the transported goods to adhere to the magnet. The magnetic flux of the lifting magnet requires a corresponding cross-section in the material to be transported, which is defined primarily by its height (material thickness).

If the length or width of the transported goods is greater than the dimensions of the lifting magnet, thin parts in particular will bend and an air gap will form between the lifting magnet and the load. This reduces the lifting capacity of the lifting magnet. Very long parts may have to be picked up with several magnets. In order to achieve the full magnetic force, the entire pole surface of the magnet must be in direct contact with the load during magnetisation. Only partially covering the pole surface is not permitted.

Influence of the surface finish

Influence of the material composition